Designing Product Protection for Greater Supply Chain Agility + ROI

Designing for Manufacturability

Design for Manufacturability – Work with Experts for an Optimized and Scalable Solution

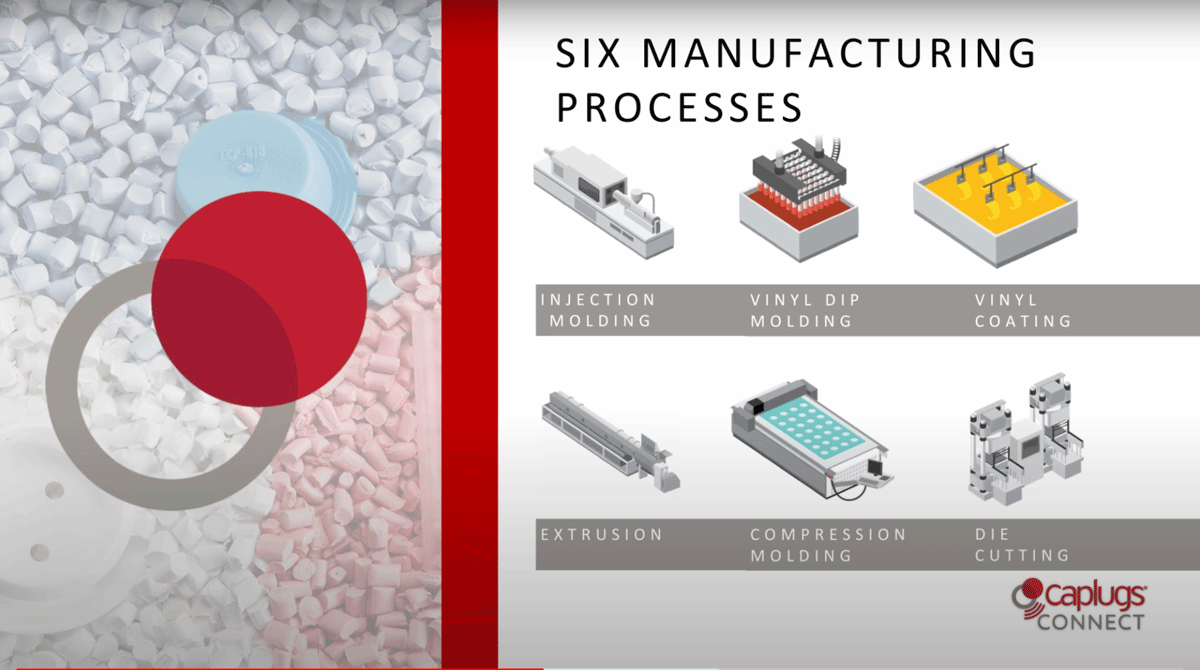

Whether manufacturers must mask an item during a coating or finishing process or protect the final product during shipping from a facility to an end user, arriving at the right product protection solution is a complex process. From shape and fit to material selection, design for manufacturability (DFM) is an approach that considers it all. As part of the Caplugs DFM approach, engineers perform a comprehensive assessment to deliver an optimized product, identifying potential design issues that can lead to production inconsistency, poor tolerance matching, or difficulties in molding that could lead to short-fills, surface defects, or unintended weakness in the final part. Join Clint Badowski, Design Group Leader at Caplugs, to learn how DFM can optimize the design for a higher performing, more consistent, and scalable part protection, as well as product improvements, mold longevity, and efficiency.

Have a question about anything discussed in the video?

Inspired by this Session?

Questions

Have general feedback or a question? We always appreciate hearing from you and are here to help.

Connect

Ready to talk with one of our sales experts and explore our innovative solutions? We’re ready to talk with you!

Solutions

Caplugs is your partner for start to finish solutions. Learn more about how our packaging and processing solutions can solve critical pain points and give your brand the competitive edge.